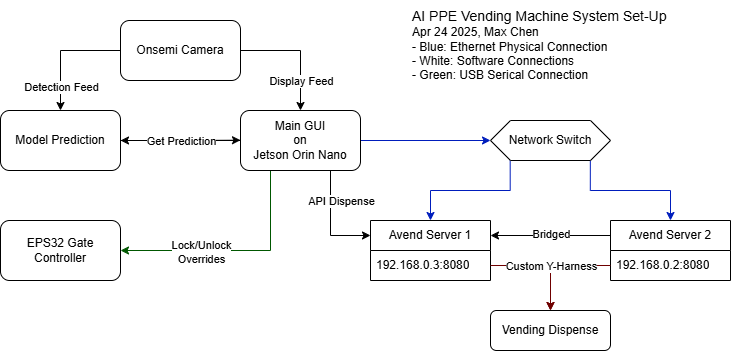

Our PPE A.I. Vending Machine integrates several subsystems into a cohesive solution:

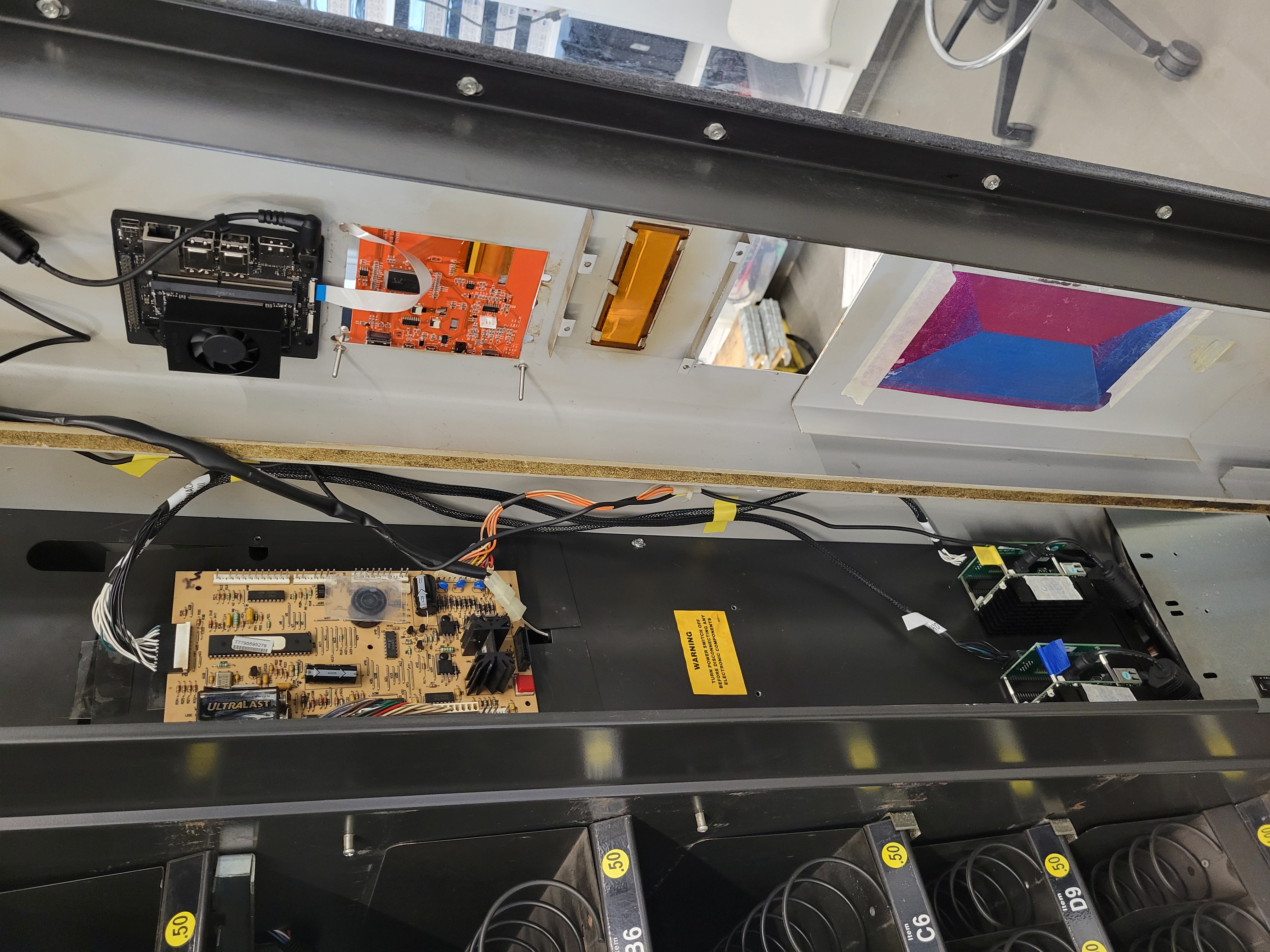

Core Components

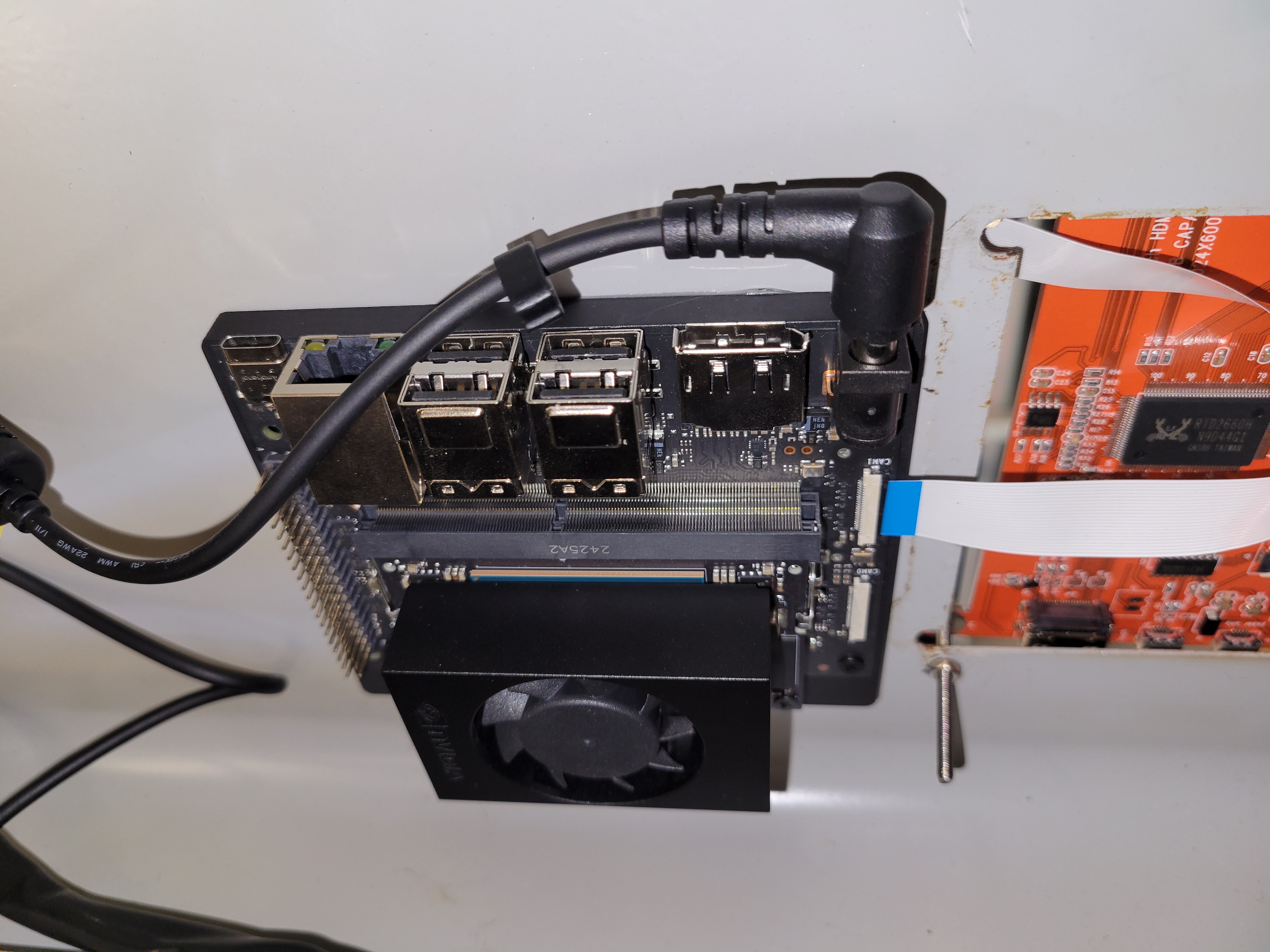

- Vision System: Camera and AI vision processing for PPE detection

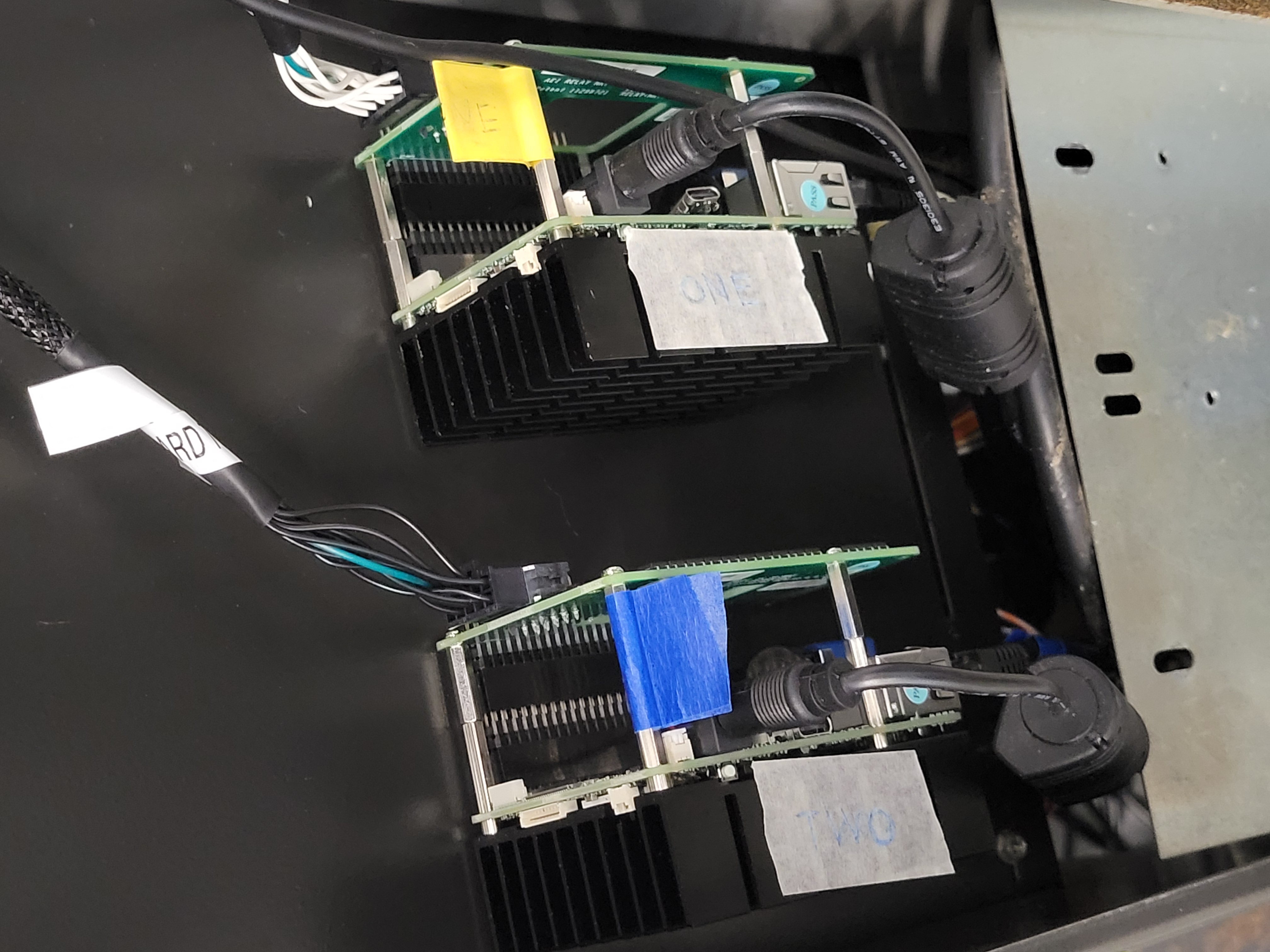

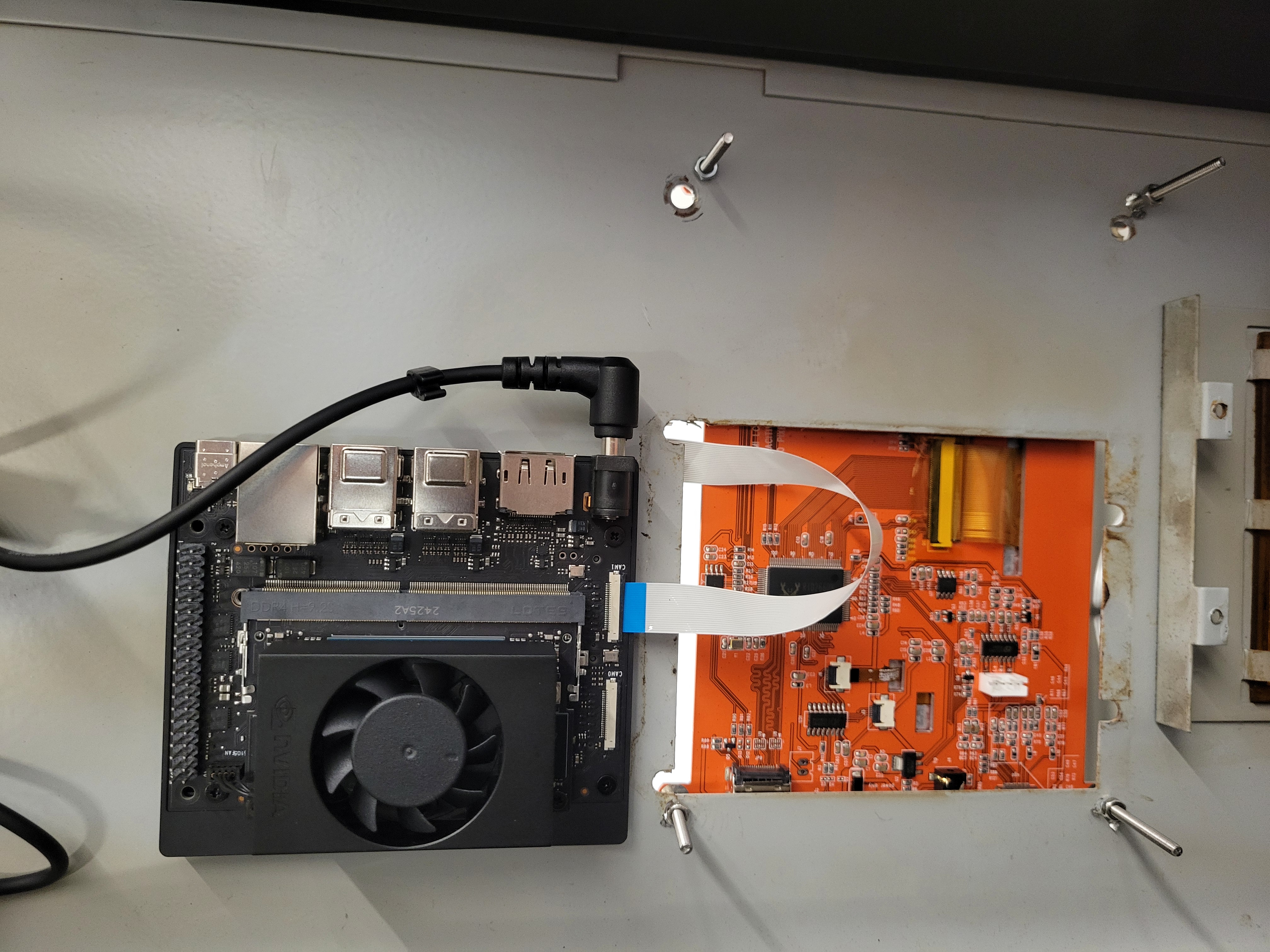

- Control System: Central computing unit managing the entire workflow

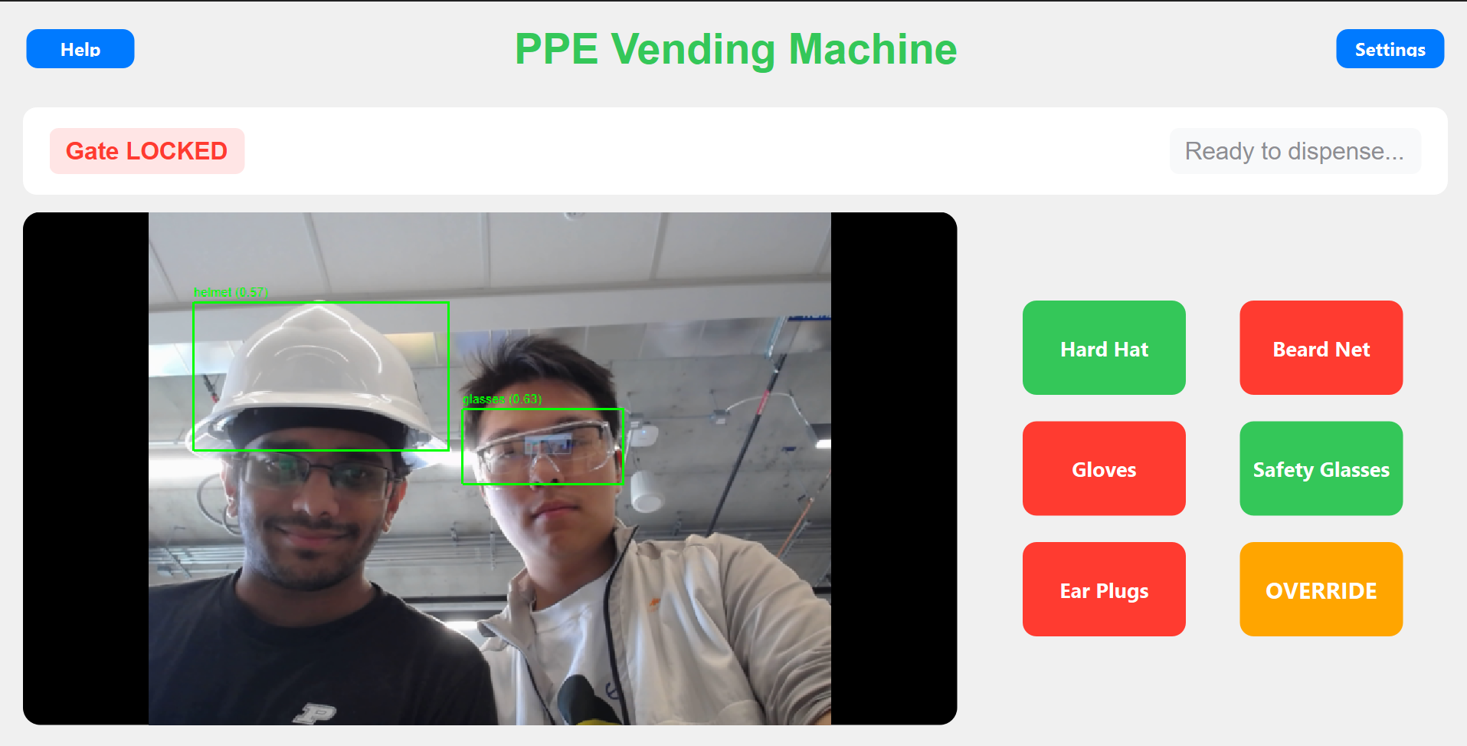

- User Interface: Touchscreen display for user interaction

- Dispensing System: Vending machine for delivering PPE items

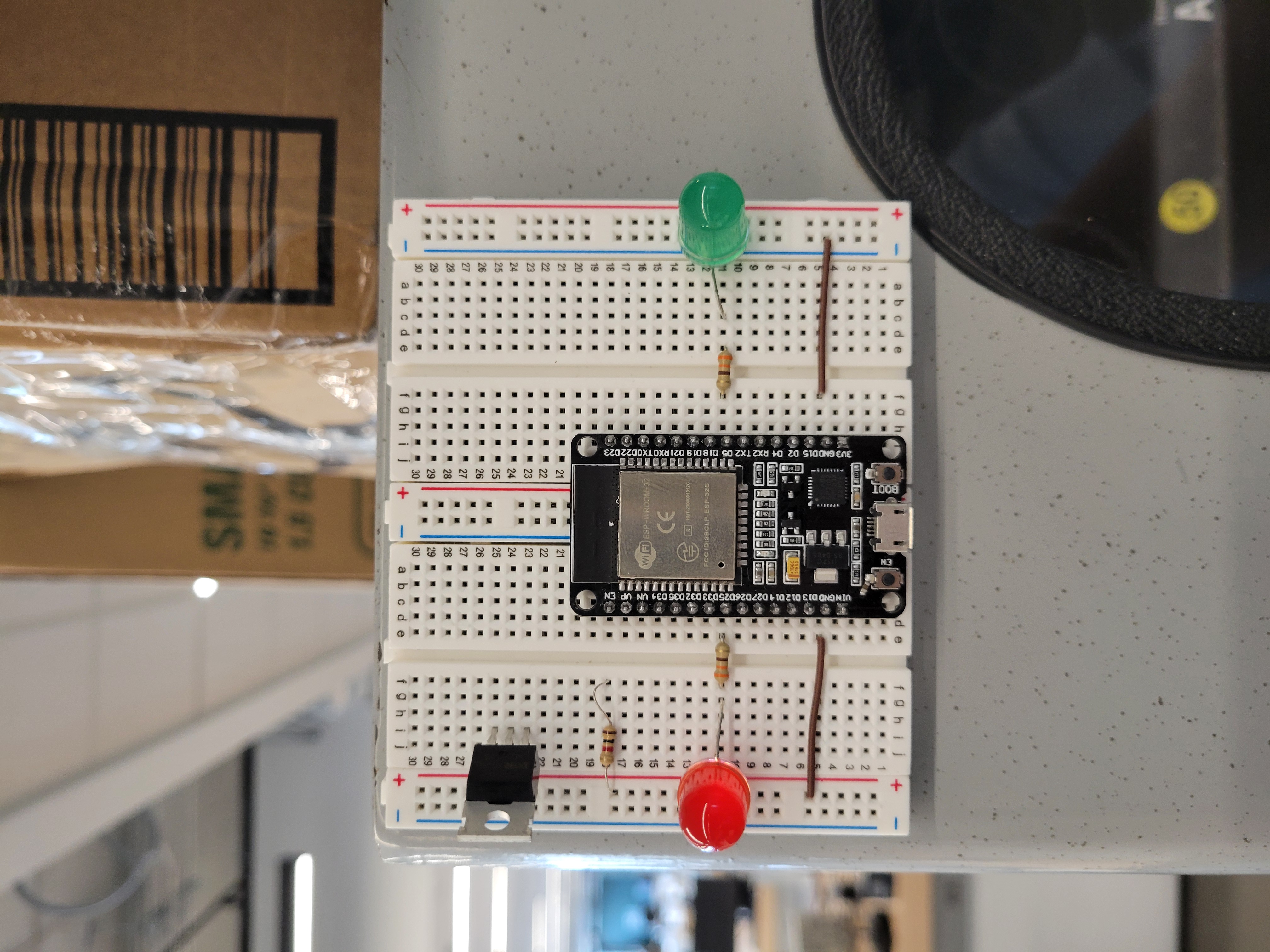

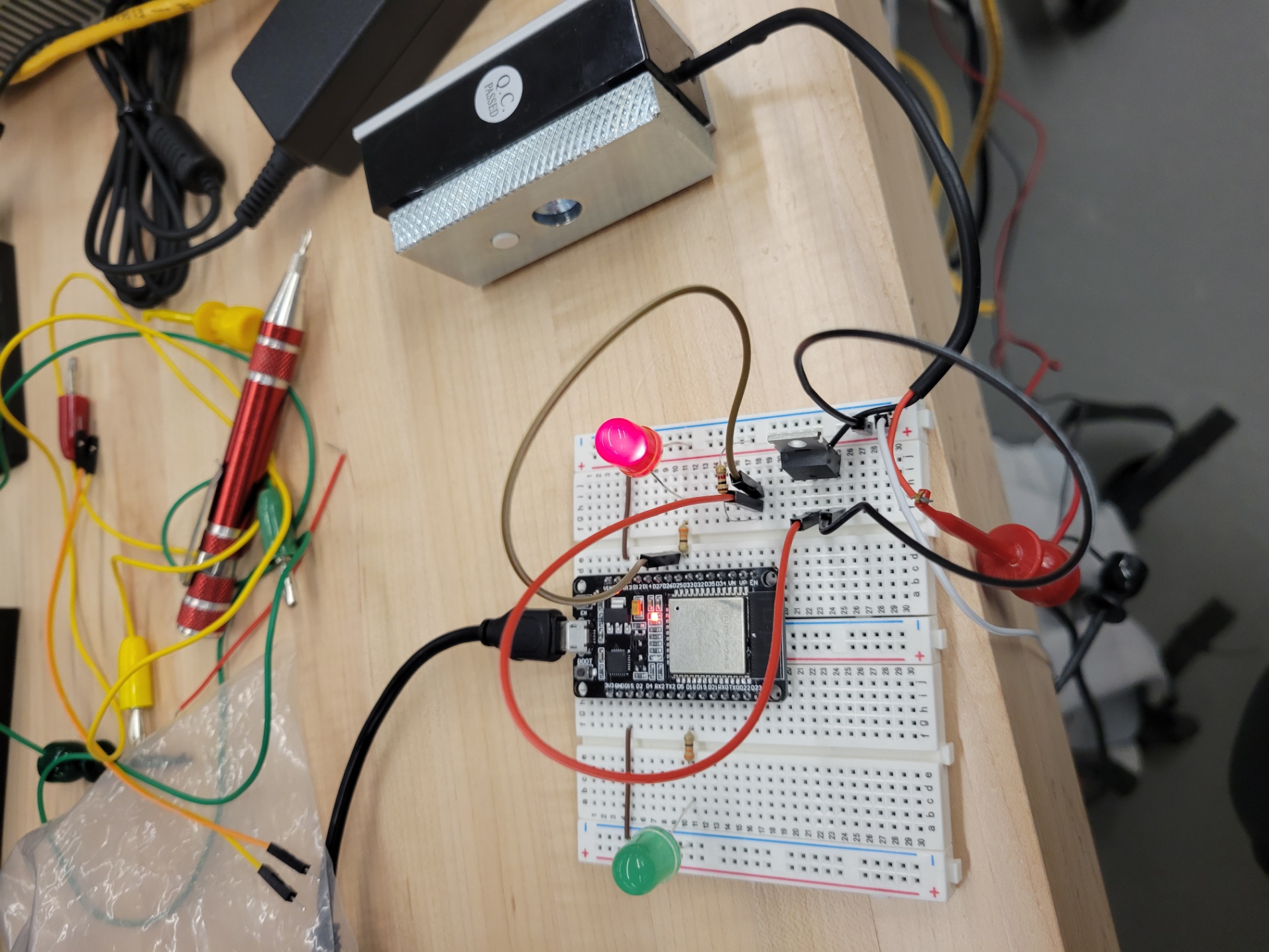

- Safety Gate: Access control mechanism based on compliance status

Data Flow

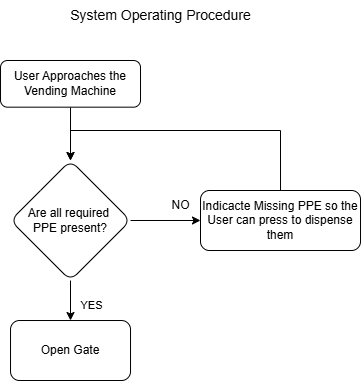

The system operates in the following sequence:

- User approaches the machine and is detected by the camera

- YOLO vision model analyzes the camera feed to detect PPE items

- Results are processed by the computing system and displayed on the GUI

- If compliant, the safety gate unlocks; if not, missing PPE is identified

- User can request dispensing of missing PPE items through the interface

- System dispenses requested items and re-evaluates compliance