Ensuring factory-wide workplace PPE compliance is a significant challenge. Traditional monitoring through manual checks or signage frequently results in team injuries due to inadequate PPE usage.

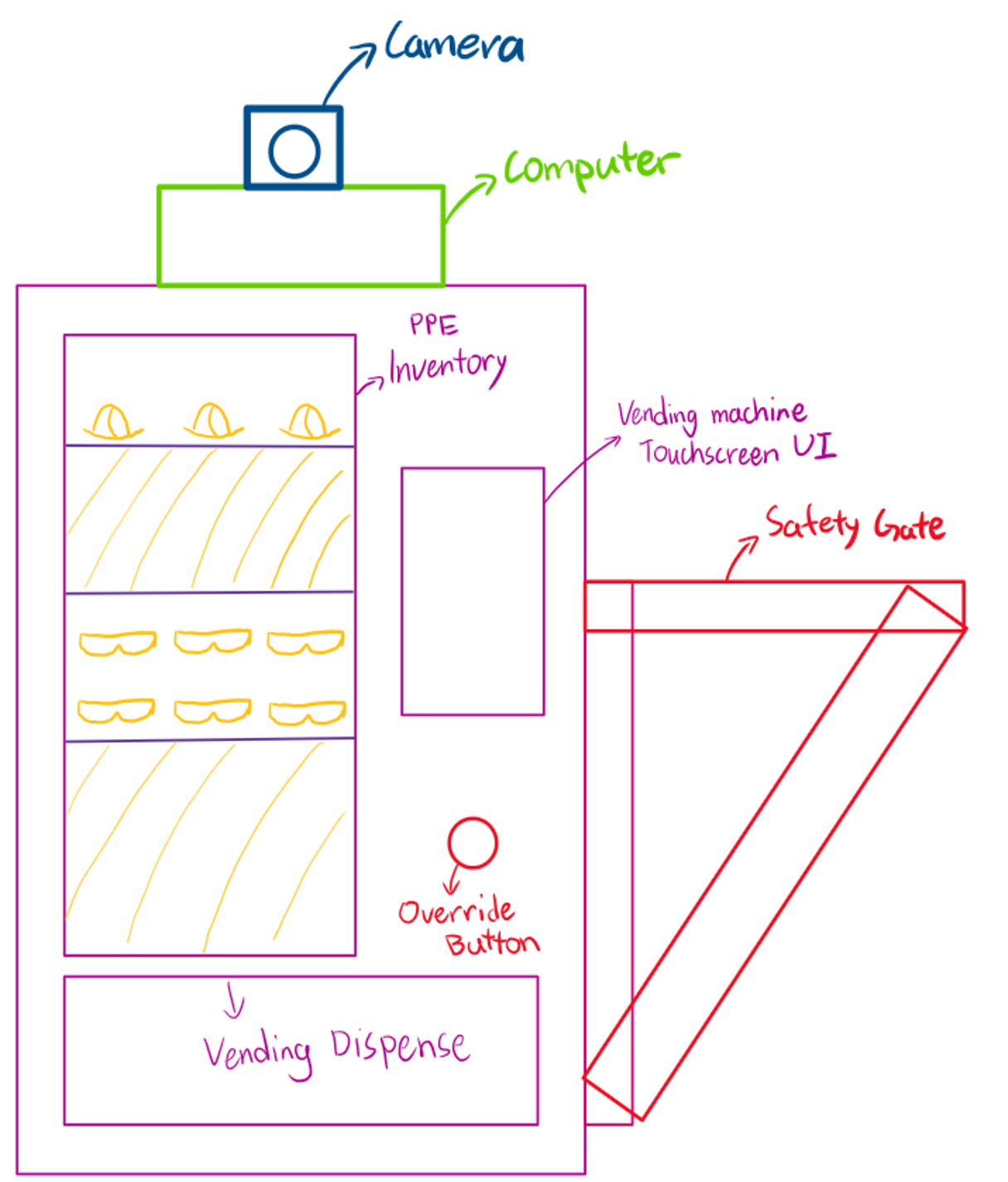

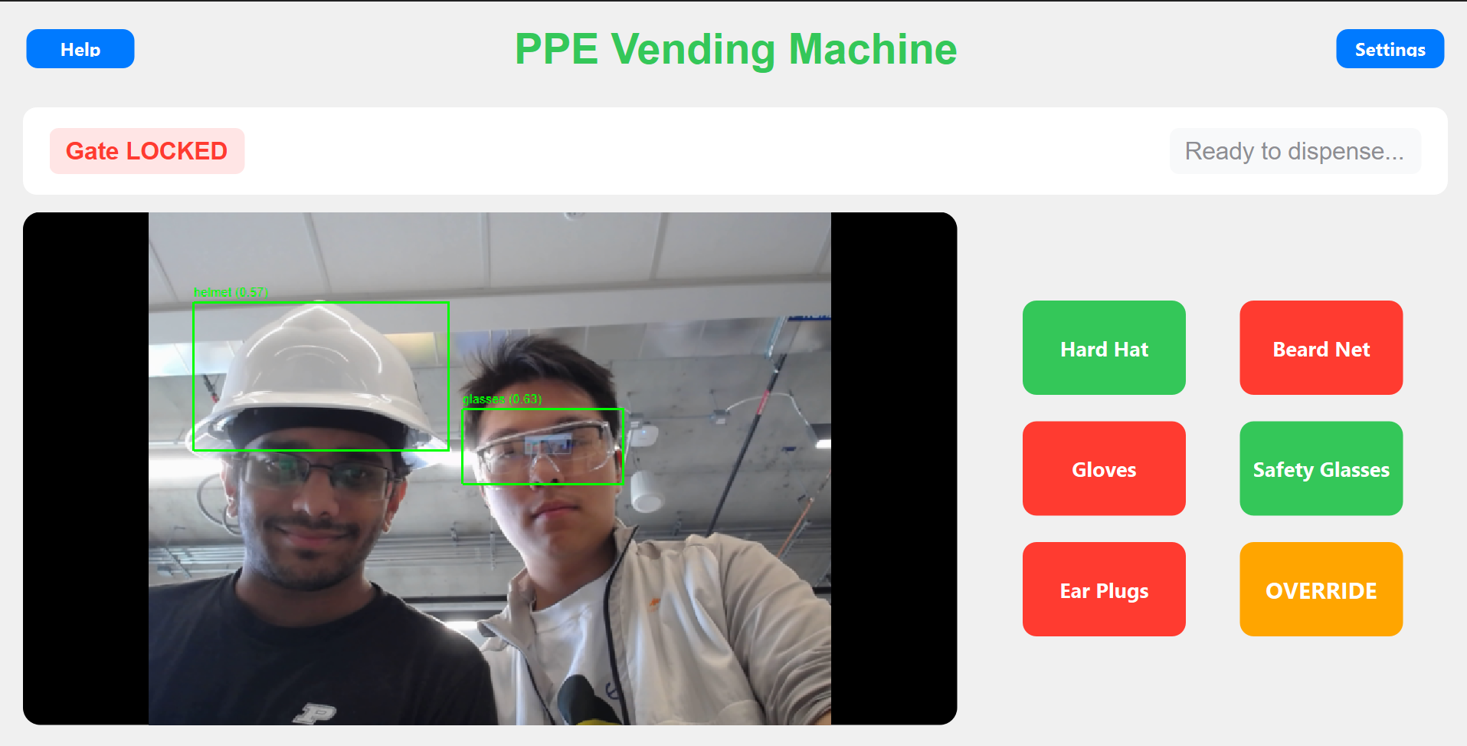

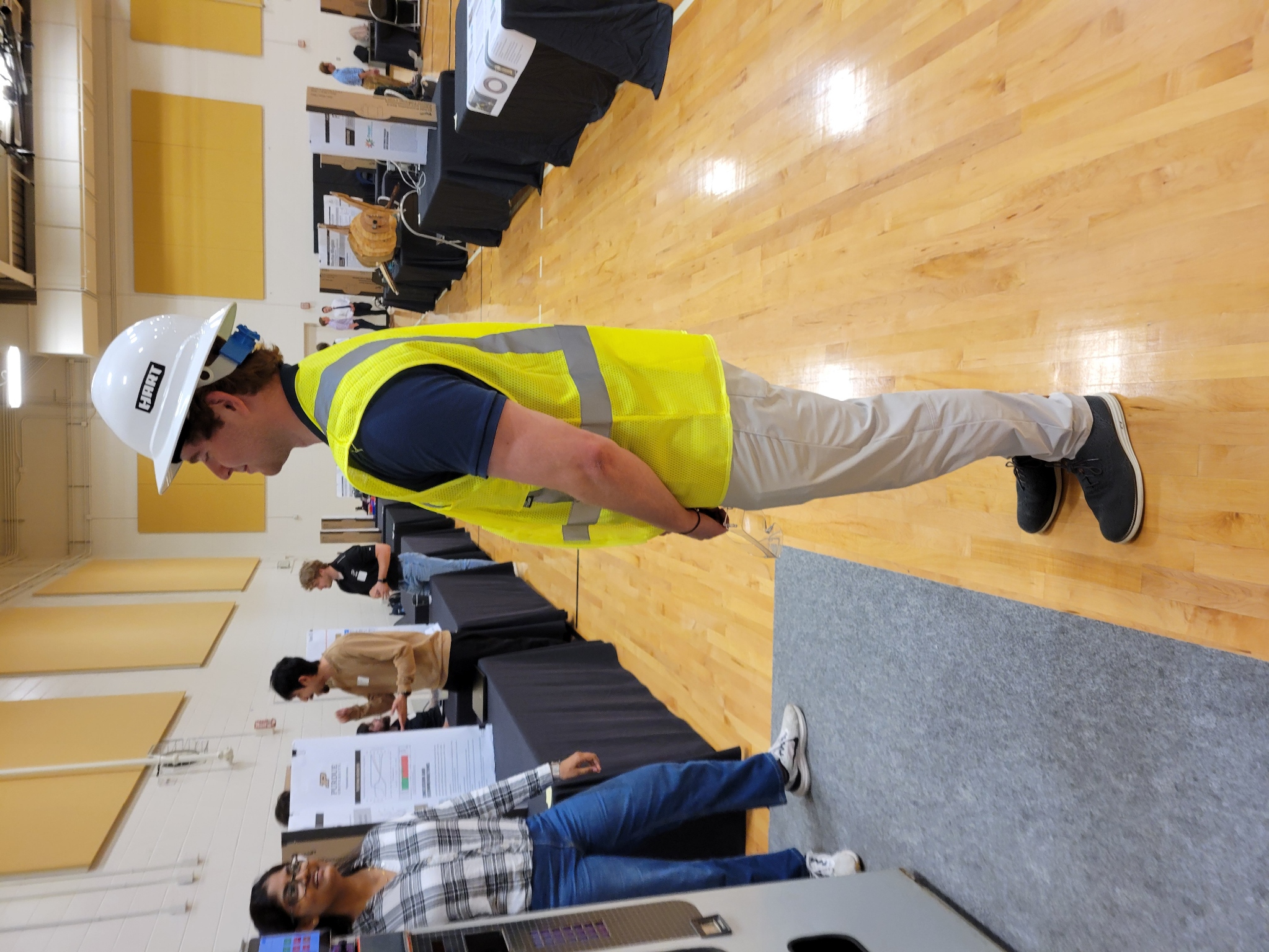

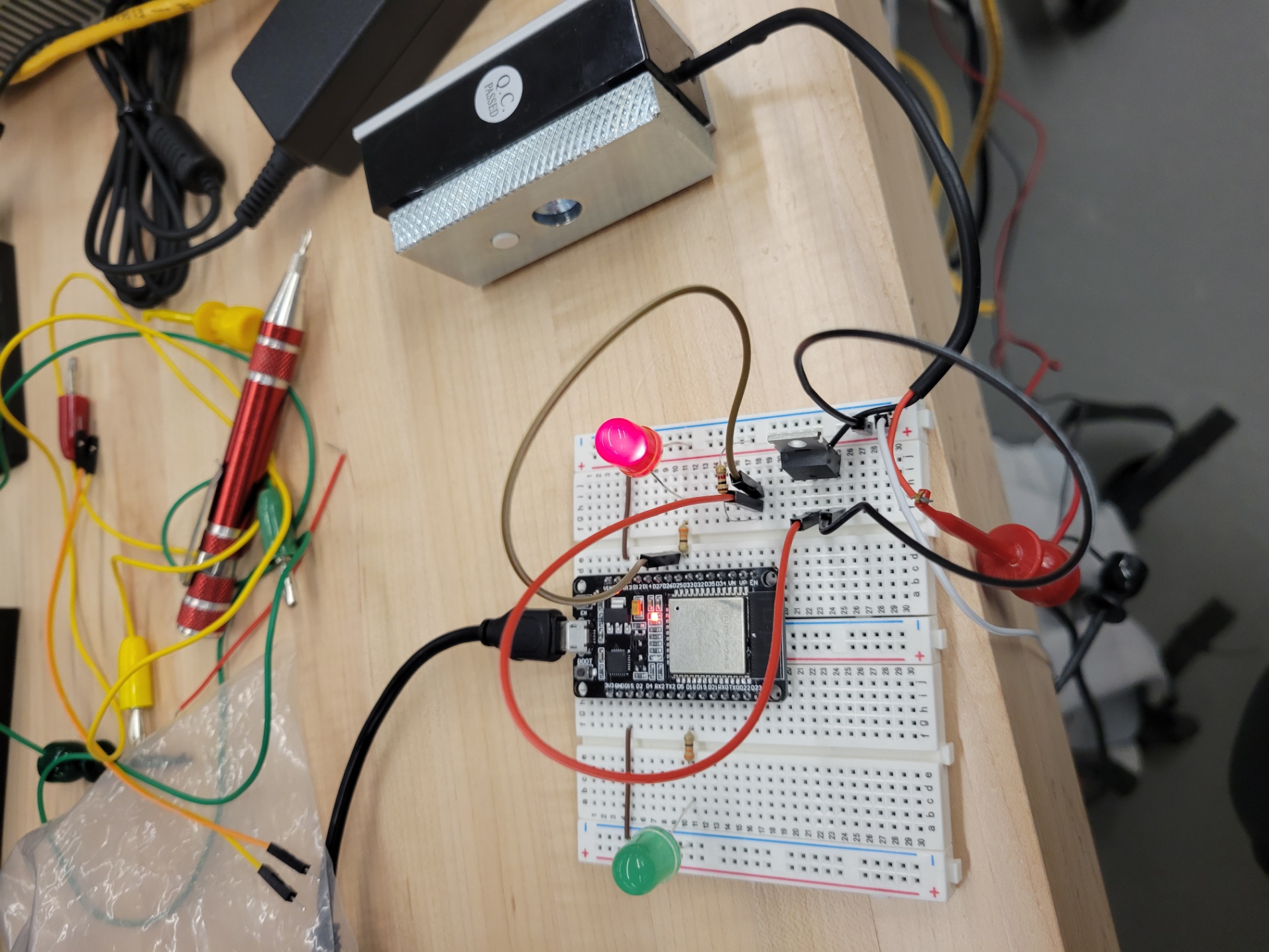

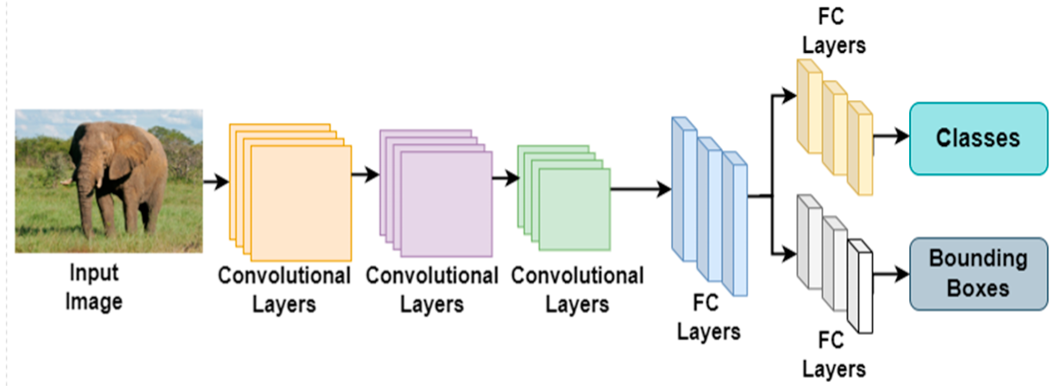

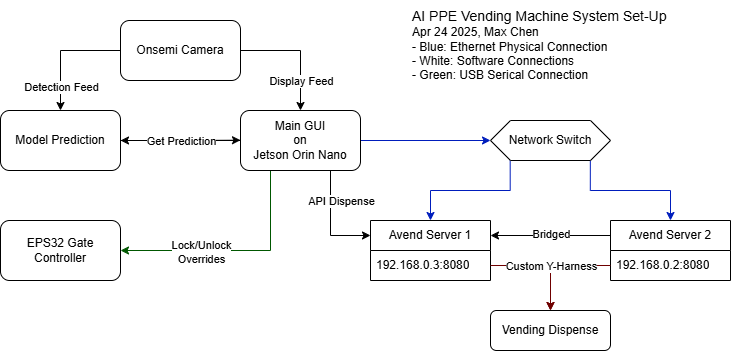

Our team has developed an intelligent vending machine system to combat this issue, utilizing AI camera technology to sense if a worker wears correct PPE and a deployment system to properly dispense missing items to them.