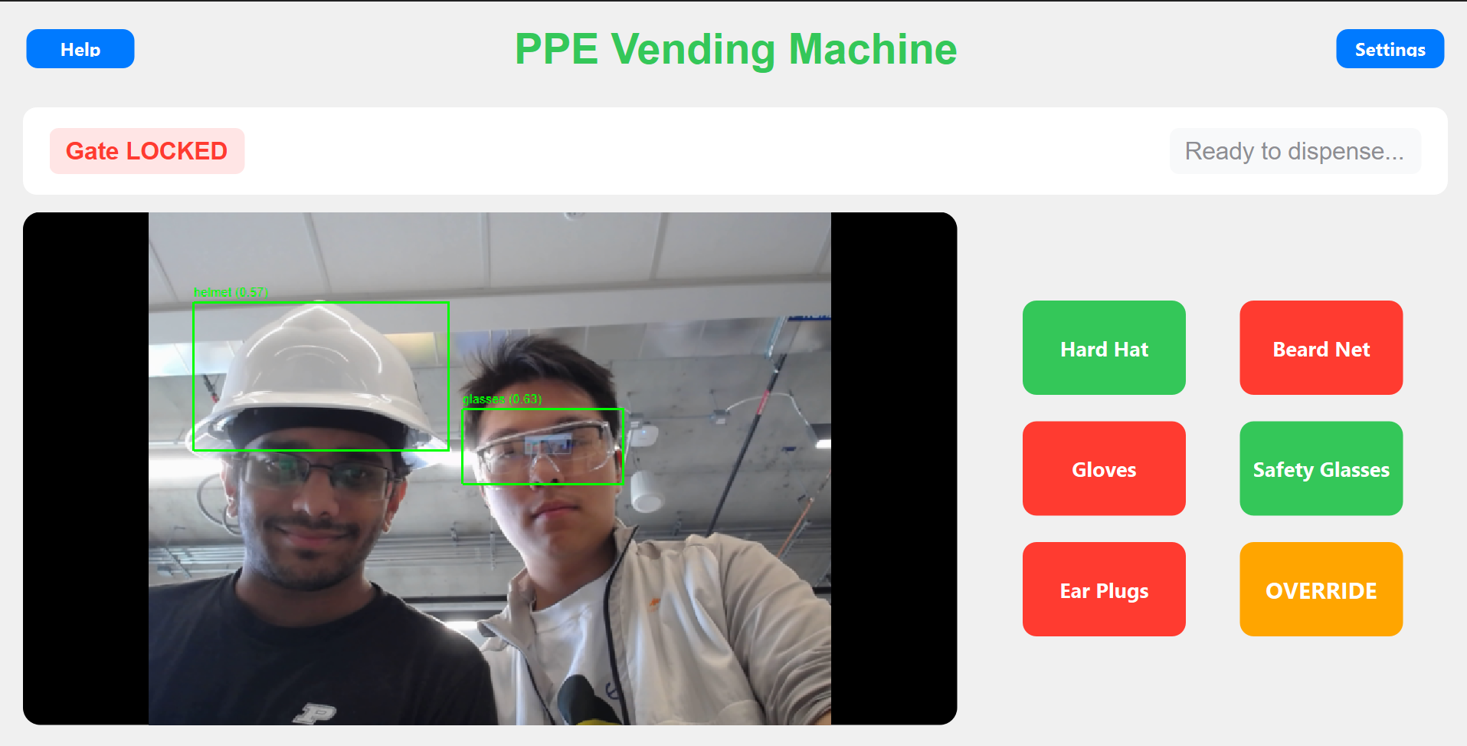

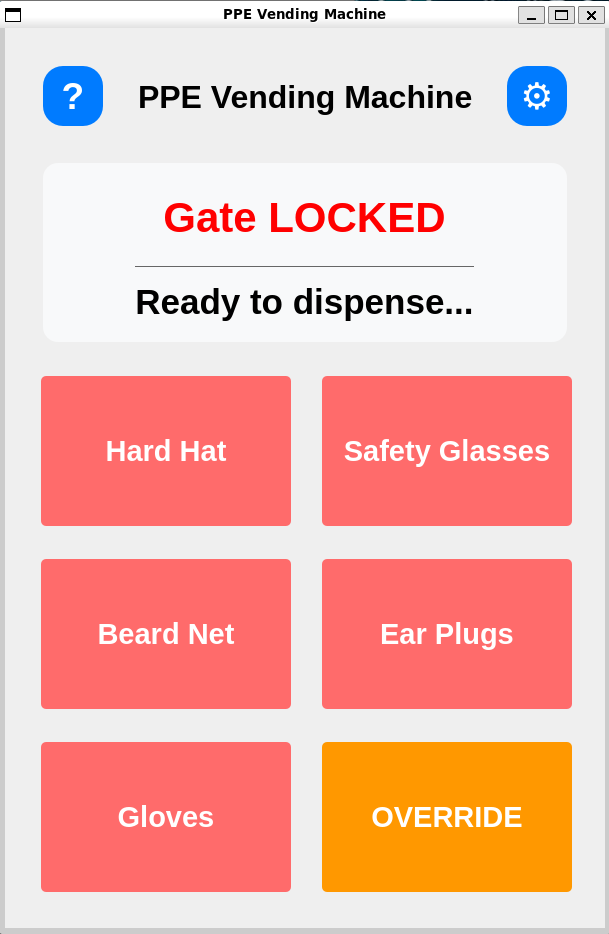

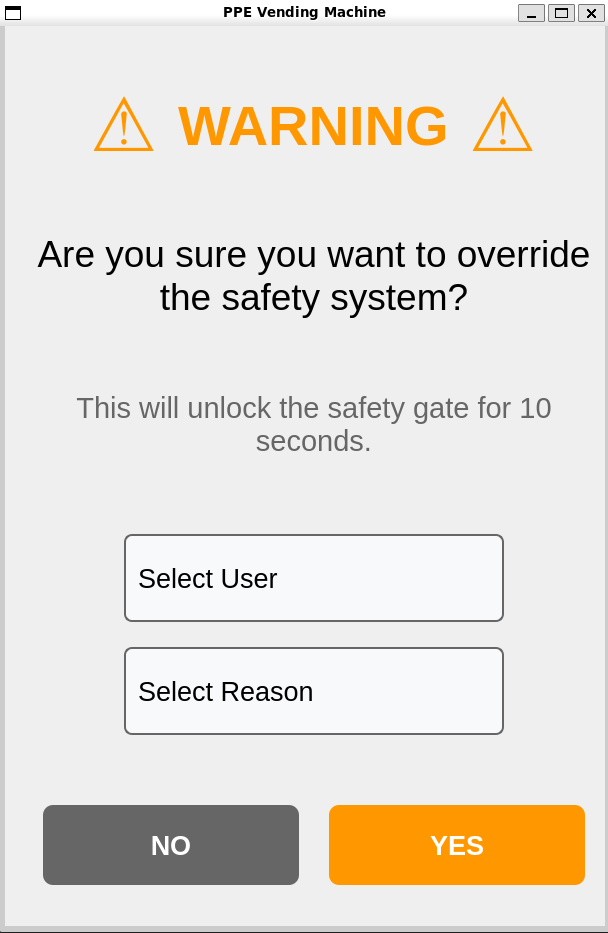

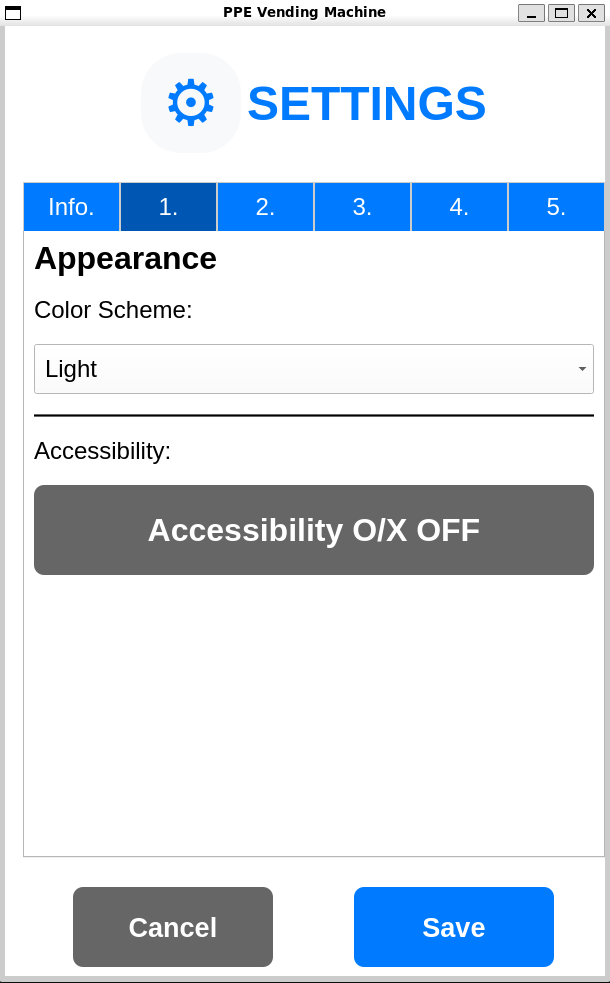

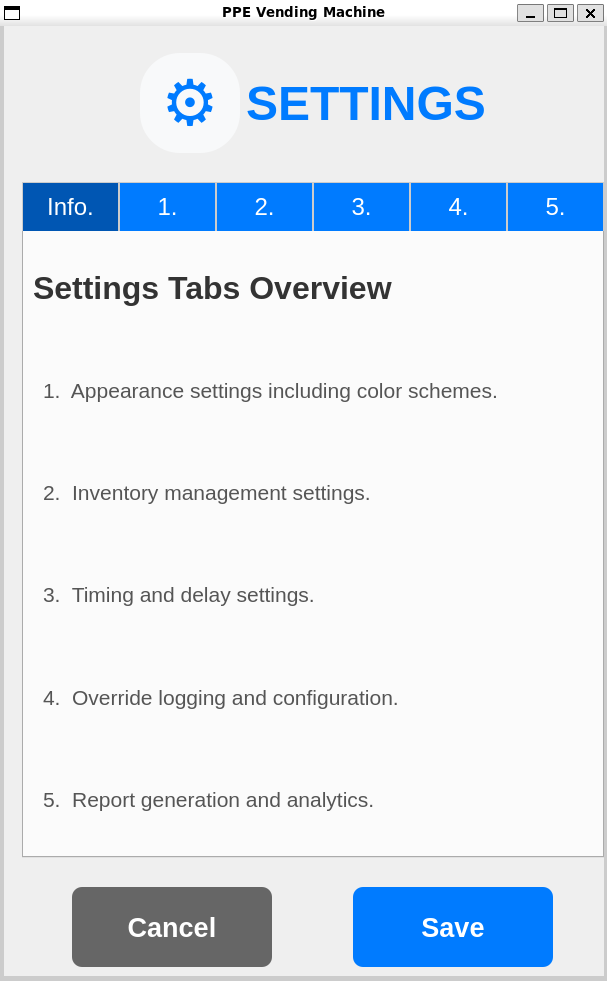

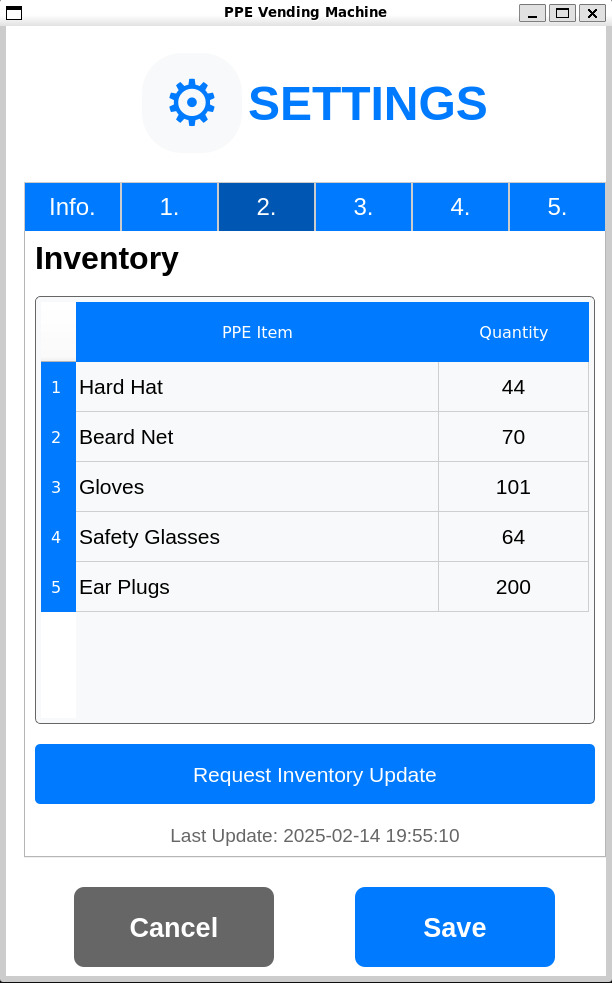

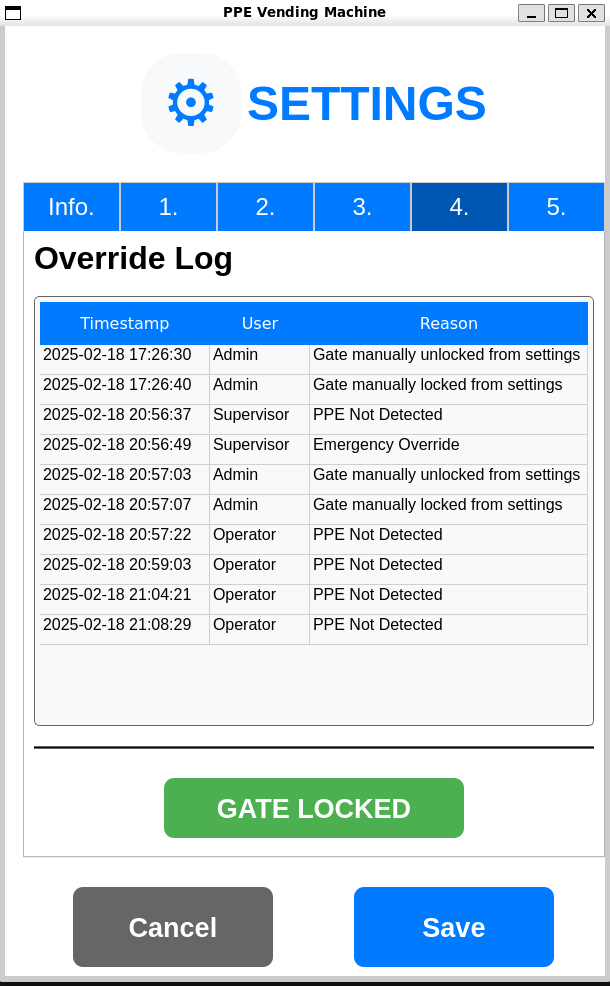

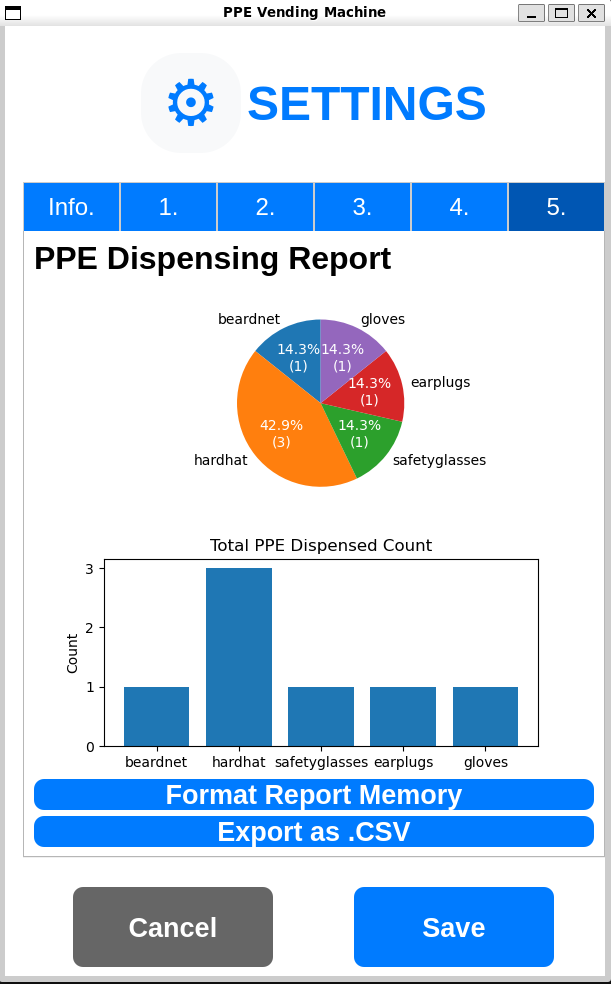

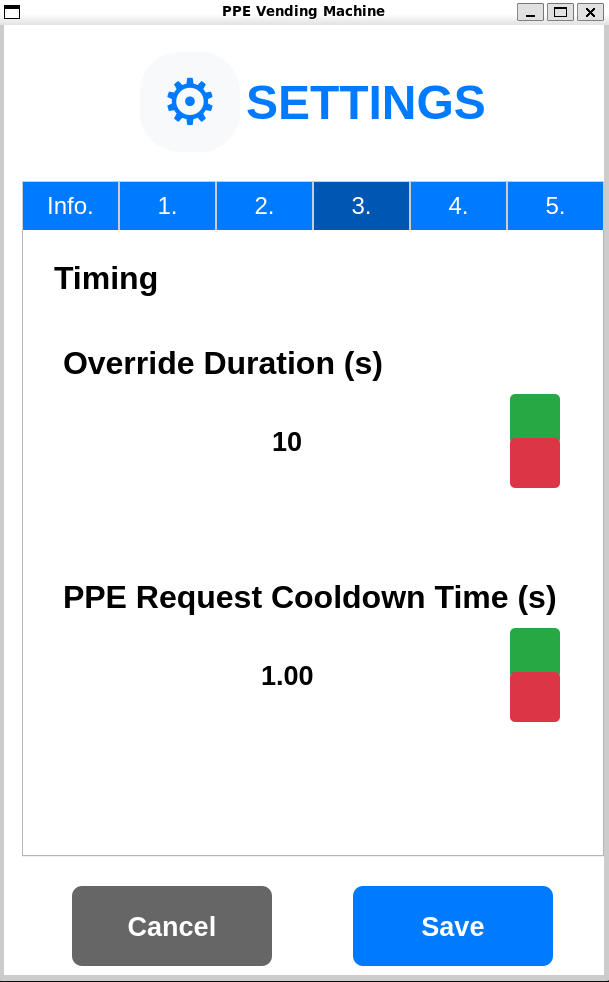

The current GUI implementation is built with PySide6, providing a functional but basic user interface. There are several key areas for improvement:

Previously a PyQt5 version of the GUI was created with additional features, but it was replaced due to the Jetson not being able to run ROS2.